In today’s environment, we are facing unprecedented, macroeconomic challenges. A successful project requires a different level of stakeholder alignment, collaboration, communication, and planning. Never, in our business’s history, have we experienced significant growth and demand on one hand, yet the effects of a pandemic, labor shortages, supply chain disruptions, material inflation, and shipping challenges on the other hand. In normal times, one of these challenges would pose a risk to the project but, in today’s environment, all of these risks are occurring AT THE SAME TIME.

It’s important to be mindful of the impact of these challenges and what we can do together to successfully navigate through these obstacles. Successful Project Management is based on building a plan with a predictable outcome. This is achieved by applying resources within a given time frame and budget while predicting and mitigating all risks.

So what are the main risks we are facing, how does it impact all stakeholders, and what can we do together to control schedules and hold down costs.

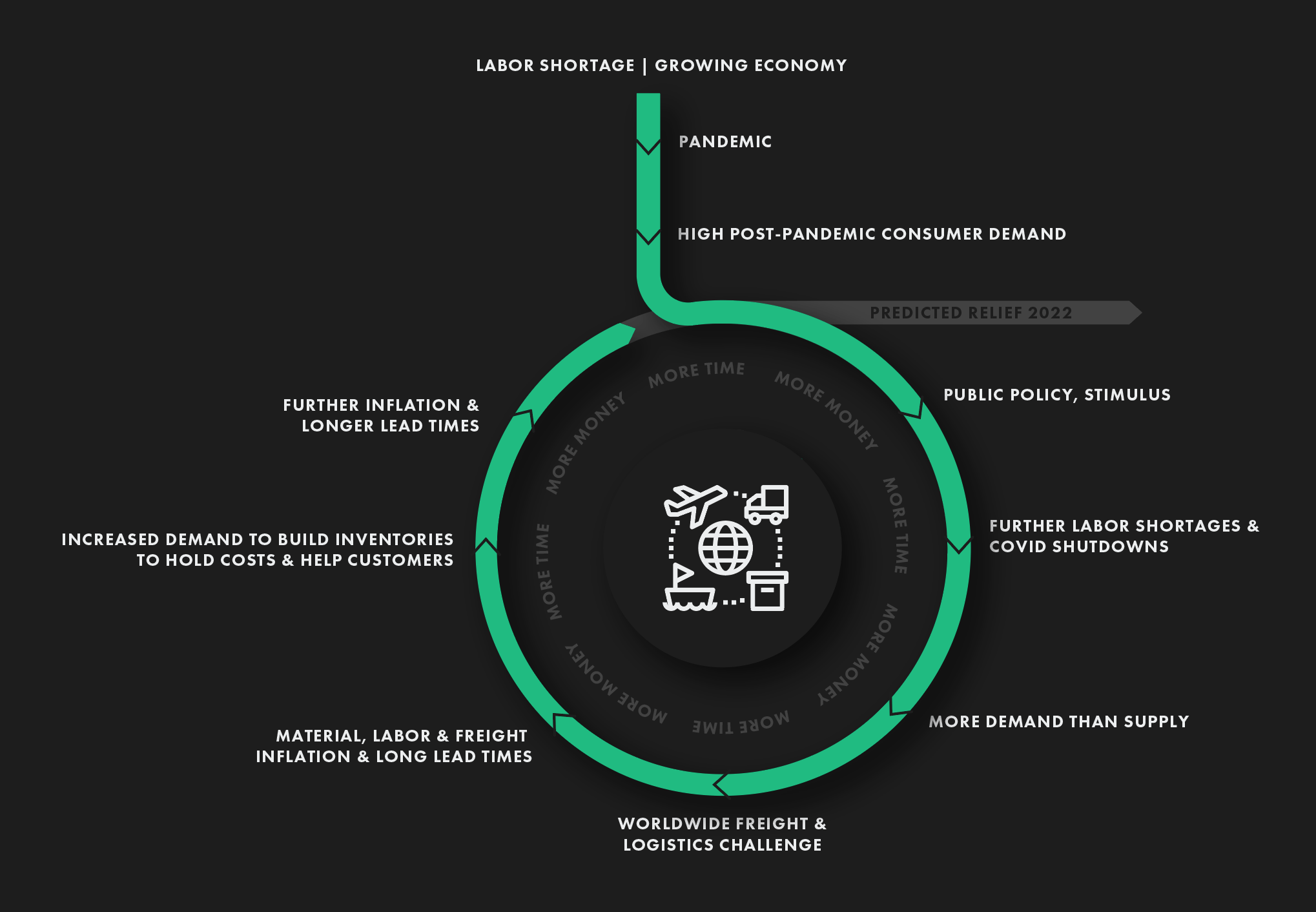

While it’s no surprise, much of what we’re facing stems from the high demand of a post-pandemic recovery combined with a vicious cycle of challenges. We entered the pandemic with an already tight labor market. Protocols from covid exposures and pandemic restrictions have resulted in unexpected and significant disruptions in skilled labor, general staffing and all areas of the supply chain. We’ve seen a COVID exposure unexpectedly shut down half of a manufacturing plant erasing thousands of hours of capacity.

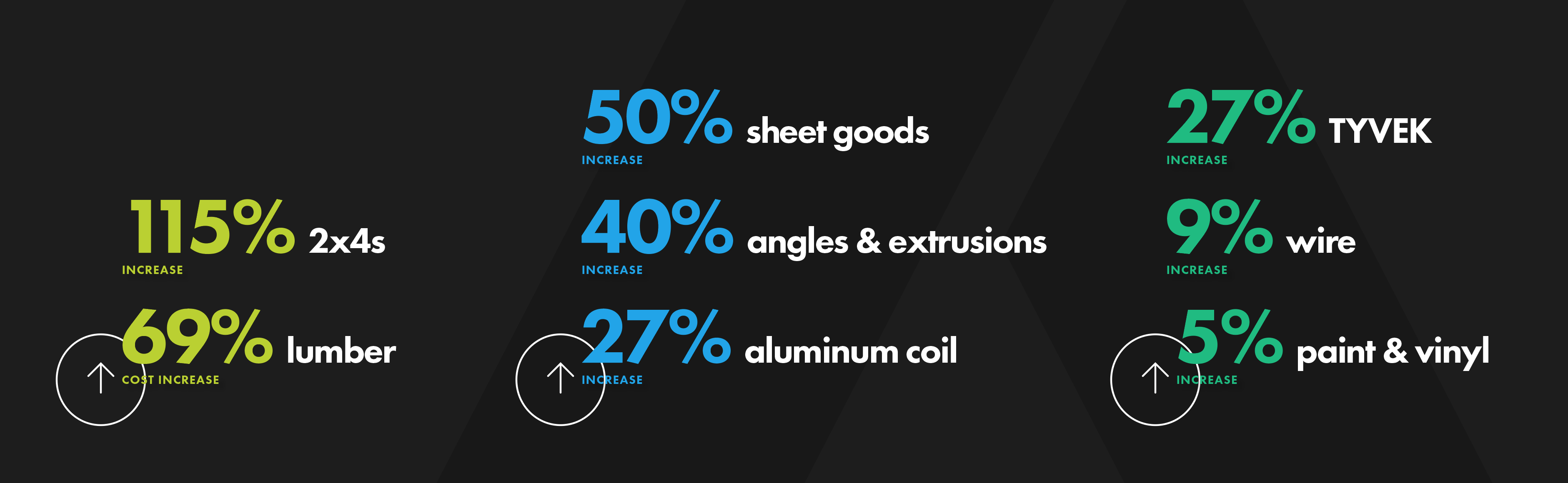

The supply chain disruption at peak demand, caused delays and inflation across raw materials, manufacturing, freight and installation. We’ve seen raw materials increase from 10-115% in our industry alone. In order to hold costs down, people are rushing to order more to stock material causing more pressure on the supply side leading to even more delays and cost increases across the supply chain. We are currently in that cycle.

As if this isn’t enough, the staffing shortages also impacted municipalities across the country causing delays in permitting and inspection approvals. All of these obstacles pose a significant risk to project schedules and budgets. Without better planning, cost overrun is a guarantee but more importantly, market conditions are such that not allowing time for planning, at worst, will mean missed dates and unhappy stakeholders.

So .. what are some best practices we as stakeholders can do to overcome these challenges?

- We need to be transparent about the risks we’re all facing, communicate clearly and make sure we’re aligned.

- We need to double down on planning and process using grit and agility as a backup plan.

- We want to encourage stakeholders to release projects earlier and make decisions faster wherever possible in the project process. This will help mitigate risks if any one area of the project experiences an inevitable delay.

- When able to do so, you should explore releasing projects in bulk to maximize efficiencies and economies of scale in every area possible. This allows you to purchase bulk materials at a discount and roll up manufacturing to get production economies, all of which will hold down costs and keep projects on schedule.

- We want to do our best to be realistic about schedules and hold planned install dates across every area of construction. If you end up canceling installations days before because a contractor isn’t ready, it may not be as easy to remobilize the minute the site is ready.

- Consider some flexibility in materials and construction methods: Use this option sparingly, and never do this without discussion and approval from your partners and be certain it does not impact the brand or quality of the product.

In closing, we are in unprecedented times. The better we communicate and work together with all stakeholders the more successful we’ll be.